Our steel ladders are meticulously fabricated to provide safe access to services inside and outside your building. Safety is key here, which is why ladders, staircases and platforms are subject to so many industry-specific regulations, and why you should always use a professional steel fabricator to undertake the work.

Structural steel ladders – an introduction

Steel ladders – fixed or portable – provide a strong and durable way of scaling a height. Mild steel and stainless steel are both weatherproof for use outside, and tough enough to withstand many years of harsh industrial conditions.

At FEM, we can fabricate steel ladders, steps, and staircases using your design or one of our own. We can also add in extra safety features, such as a handrail, an access platform, or a step-over.

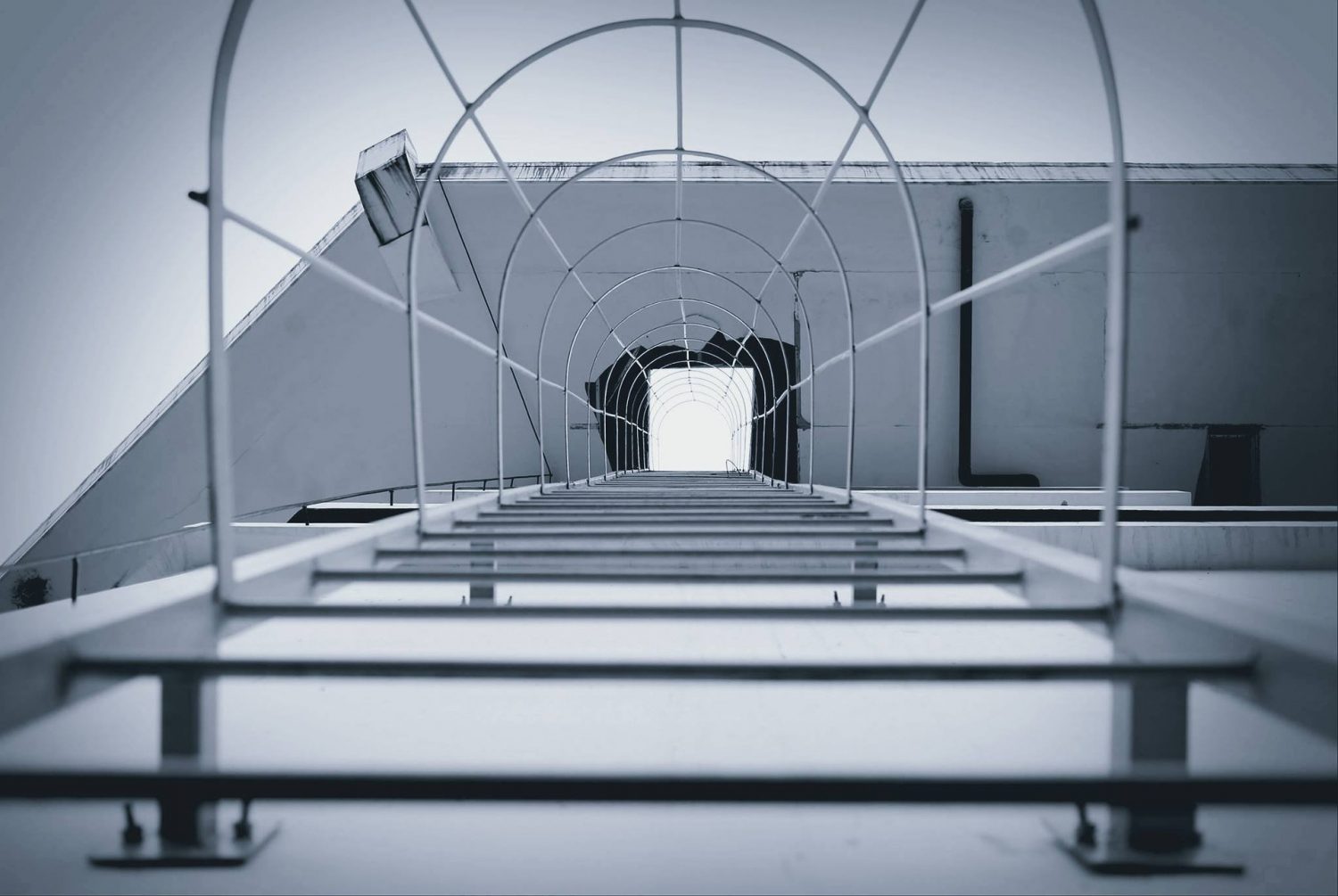

For exterior use, cat ladders or vertical ladders are a popular solution. They’re usually fixed to a wall or roof and fitted with a protective cradle, offering a way to safely access hard-to-reach areas.

The consequences of something going wrong while an employee is working at height are likely to be life-altering for everyone involved. Always make sure your chosen provider is following all of the necessary regulations for ladder fabrication.

Why choose FEM for your steel ladders

If you’re looking for steel fabrication services in Great Britain, then where better to find a provider than in the steel city itself – Sheffield. We’re a family-owned business, driven by a determination to offer our clients the very best this renowned city has to offer.

We’re also proud to say that we meet the standards for ISO9001 accreditation. When you choose to work with us, you can expect to receive a consistently high standard of work. Our reputation is everything, and we can confidently say that our approach to handling projects, from start to finish, has earned us loyalty among our clients.

To find out more about our fabrication services or to discuss steel ladder fabrication, call our team, email us, or use our contact form online.