Aluminium Fabrication

Aluminium Fabrication

FEM are leading experts in manufacturing aluminium sheet fabrication in Sheffield. Our aluminium metal fabrication service is a highly quality service and our senior fabricators with many years’ experience under their belt, work to ensure all completed projects meet high levels of excellence and certification.

Aluminium is robust and durable, making it a long lasting material to use whilst being flexible and versatile due to the ability to form any shape and size during the manufacturing process. If you project requires a material that is a great conductor of heat and electricity, corrosion resistant and easy to install then aluminium is the perfect material.

Aluminium fabrication can be used for:

- Packaging

- Windows and door frames

- Construction

- Aerospace industry

- Electrical applications

FEM Ltd has 30,000 sqft of workshop space with a highly skilled team and array of tools machinery and experience. When designing and manufacturing projects, we work alongside our ISO 9001 quality accreditation and BS EN 1090 (Exc. class 3 welding) accreditation to ensure all of our projects are accountable and follow strict guidelines to meet a high level of excellence.

Aluminium fabrication process

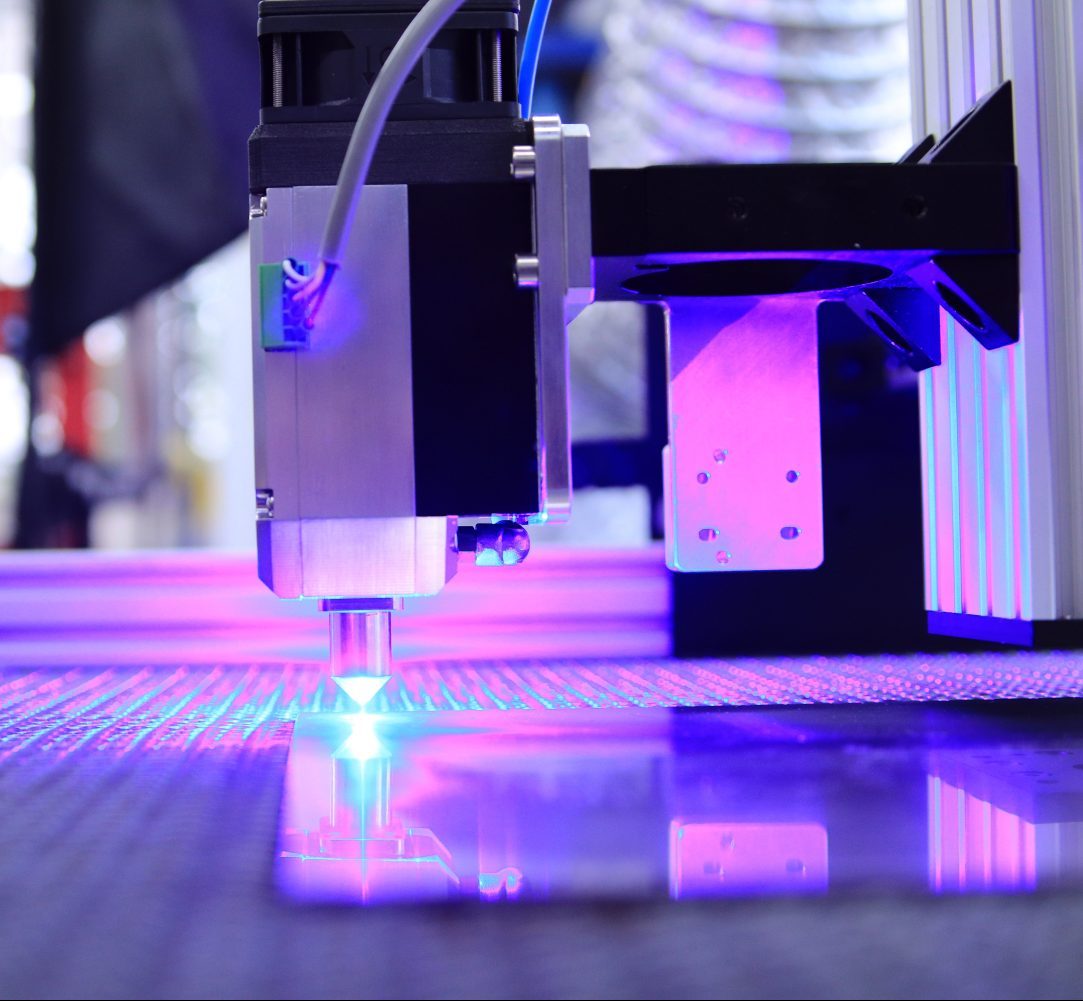

Fabricating aluminium requires expert and precise fabrication engineering skills to join all the parts together. Aluminium can be manufactured using the same fabrication methods for other metal fabrication. Common methods of this type of fabrication include:

- Extrusion

- Drawing

- Machining

- Forming

- Castings

- MIG and TIG Welding

- Waterjet Cutting

FEMs metal fabrication process begins with an idea, design, or drawing being supplied to our estimating department before a technical review is carried out. This is to ensure we have the correct skillset, accreditation, and machinery to carry out the metal work required. We will also be able to advise you on the right steel to use for your project whether it is mild steel, stainless steel or aluminium steel.

From here it will be passed to our fabrication team who will manufacture the products to an accuracy of millimetres. The final processes involves the mild steel being passed onto the welding team who will work on the correct procedure before going through its relevant NDT. The final products will be signed off and certified to BSEN 1090.

Aluminium vs Steel

Aluminium and Steel are often compared to one another as they are both strong metals. Depending on the metal products and requirements needed some people may opt for steel and some may opt for aluminium. Whilst both are strong metals, Aluminium is a much more lightweight material compared to steel and can be transported. Steel is a heavier and firmer material and can be used. Both materials provide a number of benefits for each project need.

Need Help with a Fabrication project?

Not sure where to start? At Fem we offer expert advice and guidance to point you in the right direction and help make the process smoother.

All our metal fabrication services are fit for purpose and designed and fabricated to the highest quality by a highly skilled team.

If you require aluminium fabrications or aluminium framework fabrication and have a design in mind, please get in touch with us to find out more about our bespoke fabrication services. If you need support on finding the right material or assistance on a project, we have a team of experts who can guide you.